M&M International Partnership with KLX Energy Services

M&M International Announces KLX Energy Services, LLC in Bridgeport, as New Authorized Repair Facility.

4 min read

%20(3).png) M&M International

Sep 25, 2024 7:45:00 AM

M&M International

Sep 25, 2024 7:45:00 AM

At M&M International, our commitment to excellence in mechanical engineering is foundational to our success in delivering high-performance valves. By integrating advanced mechanical engineering principles throughout the design and manufacturing processes, we ensure our valves meet the rigorous demands of the oil and gas industry. Here’s how our mechanical engineering expertise enhances valve performance and reliability.

Mechanical engineering is at the heart of our valve design process. This discipline's principles are crucial for understanding and applying the mechanics of materials, fluid dynamics, and thermodynamics to valve development. Here’s how we apply these principles:

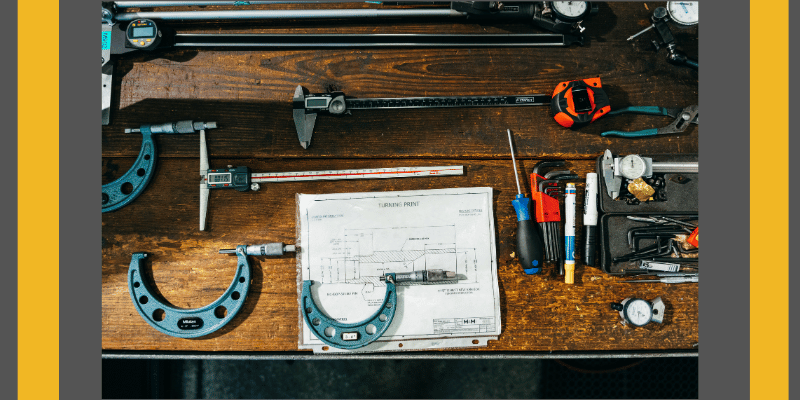

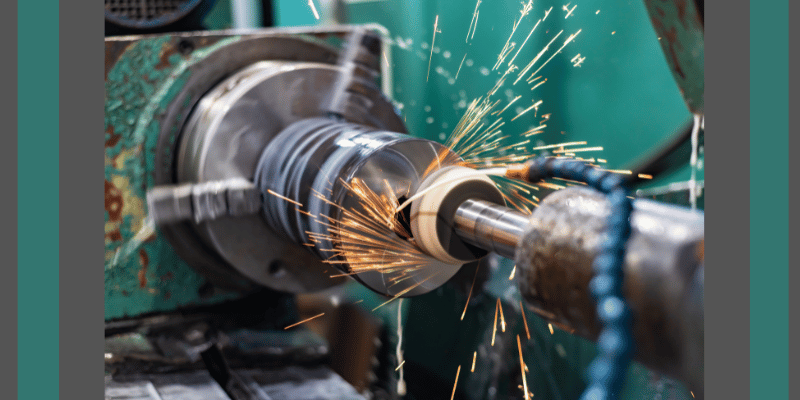

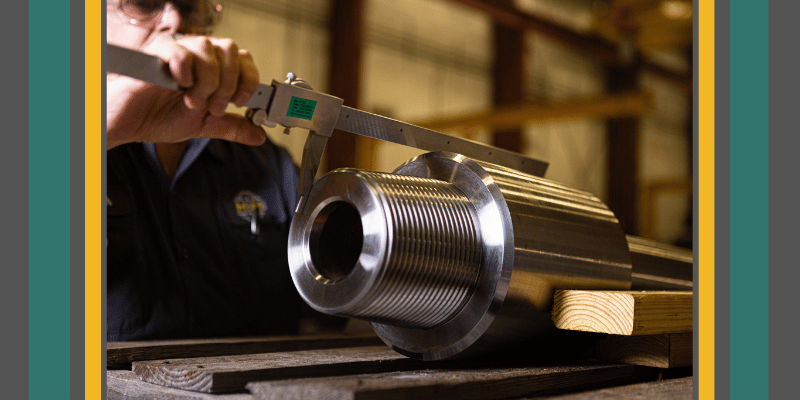

The application of mechanical engineering doesn’t stop at design—it extends into the manufacturing process. Here’s how we incorporate engineering excellence into production:

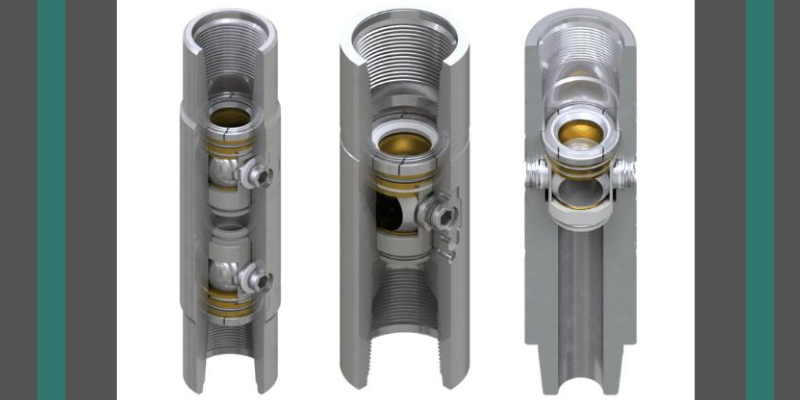

M&M International’s CANISTER GUARD® valve design represents a pinnacle of innovation in valve technology, showcasing our deep commitment to advancing mechanical engineering solutions in the oil and gas industry.

These aspects of the CANISTER GUARD® valve design illustrate M&M International’s ongoing dedication to excellence in mechanical engineering. By continuously innovating and improving our products, we provide our clients with solutions that not only meet but exceed the toughest industry demands, ensuring safety, efficiency, and cost-effectiveness in their operations.

Our dedication to leveraging mechanical engineering expertise underscores our commitment to providing top-quality valve solutions. At M&M International, we don’t just manufacture valves; we engineer solutions that push the boundaries of what’s possible, ensuring our products lead the market in performance and reliability.

We invite industry professionals and clients to discover how our commitment to engineering excellence can enhance the safety, efficiency, and performance of your operations. Trust M&M International for valve solutions that are not just built but engineered for success.

%20(3).png?width=123&height=123&name=_(250%20x%20250%20px)%20(3).png)

M&M International is a family owned and operated original equipment manufacturer in the energy industry. Since its founding in 1980, M&M has become internationally known in the industry for creating and manufacturing the most efficient, reliable, and user-friendly well control valve design in the world, namely, the CANISTER GUARD®.

M&M also manufactures a wide variety of subs, inside blowout preventors (“IBOPs”), swivels, surface test trees, offline cementing valves, and other equipment used during drilling, completion, and production operations, both on land and offshore. In addition to our products, we also offer a full spectrum of manufacturing services and stand ready to build not only our own designs, but the designs brought to us by our customers and partners.

The M&M International Team is committed to solving the most common, and uncommon, problems associated with the well control sector today. We also put forth great effort assisting our customers in solving problems associated with other aspects of the energy industry. We are a dynamic and customer satisfaction-oriented company that is focused on helping its customers improve on multiple levels, not just with their well control needs. No matter what we are doing for the customer, we deliver extraordinary service that is superior to any of our competitors.

Located at 1249 Evangeline Thruway, Broussard, Louisiana 70518

M&M International Announces KLX Energy Services, LLC in Bridgeport, as New Authorized Repair Facility.

M&M International is proud to announce that it is a licensed manufacturer of Hilong’s HLST® and HLIST® super high‑torque, double‑shoulder...

One film. One Story. One big win. We're proud to share that Outfox & M&M International have been honored with a Gold Telly Award for our cinematic

In the high-stakes world of oil and gas drilling, operational safety is paramount. Drill Stem Safety Valves play a critical role in ensuring the...

With a rich heritage spanning decades, M&M International has been at the forefront of crafting upper and lower top drive valves. Engineered...

In the complex field of manufacturing engineering, quality control inspections are not just a procedural formality—they are a fundamental...