M&M International Wins Gold at the 46th Annual Telly Awards

One film. One Story. One big win. We're proud to share that Outfox & M&M International have been honored with a Gold Telly Award for our cinematic

4 min read

%20(3).png) M&M International

Sep 20, 2024 11:59:17 AM

M&M International

Sep 20, 2024 11:59:17 AM

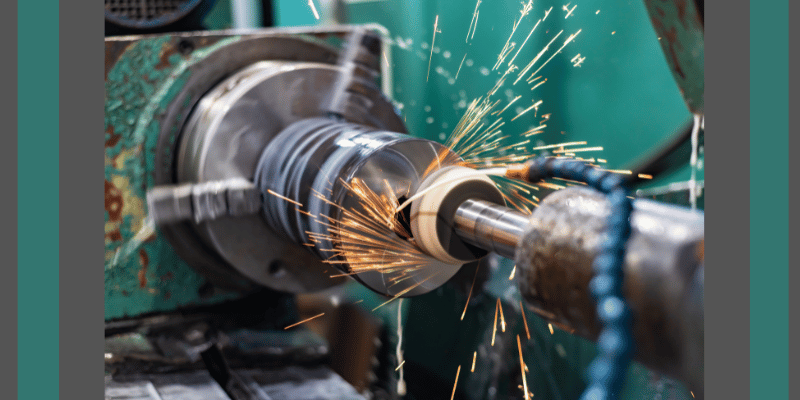

In the complex field of manufacturing engineering, quality control inspections are not just a procedural formality—they are a fundamental necessity. At M&M International, our approach to quality control is integral to maintaining the highest standards in the production of components used across our industry. This blog explores why these inspections are crucial, how they are conducted, and what specific actions M&M International takes to ensure excellence.

Quality control inspections are essential in manufacturing engineering because they directly influence product reliability, compliance, and performance. These inspections are crucial for risk mitigation, enabling the early detection and correction of defects that could lead to real-world failures, thus preventing potential safety hazards and operational downtime.

Many industries are governed by strict regulatory standards that demand rigorous product testing to ensure safety and efficacy, ensuring compliance through detailed inspections. Moreover, consistently delivering products that meet quality expectations is fundamental in building and maintaining customer trust and loyalty, which are vital for a company’s success and reputation.

Quality control in manufacturing involves several detailed processes, each designed to ensure that every product meets the required specifications and quality standards before reaching the customer:

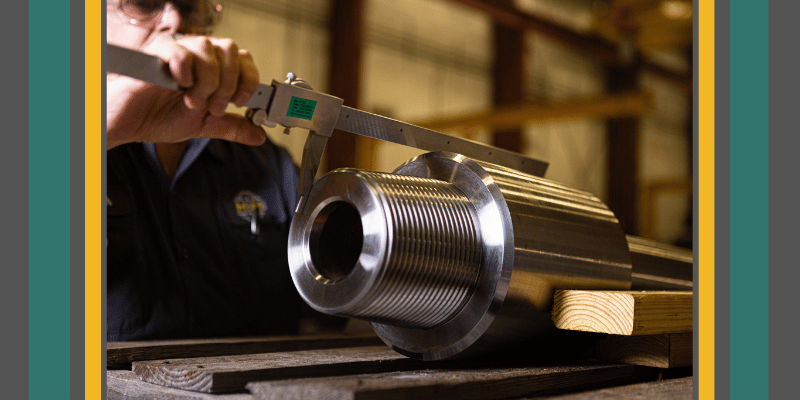

In quality control inspections, precision measurement tools are indispensable for ensuring that every component meets stringent quality standards. At M&M International, we employ a variety of precision tools and technologies to ensure the highest quality in our manufacturing processes:

Ensuring the accuracy of thread sizes is crucial in the production of components that must fit precisely within complex assemblies. At M&M International, we utilize a comprehensive array of API, Imperial, and Metric thread gauges. This vast selection allows us to verify that each component conforms to exact specifications, enhancing the reliability and safety of our products.

For dimensions that require visual confirmation, our Optical Comparator provides an essential service. This tool allows us to magnify the surface of a component, ensuring that even the minutest imperfections are identified and addressed. This level of scrutiny is vital for maintaining the integrity of our manufacturing process and the quality of our final products.

The Gagemaker system is another cornerstone of our quality control process. It helps verify the precision of thread measurements and alignments, ensuring that all components adhere to the required tolerances. This precision is crucial for the durability and performance of our products in the field.

Our Coordinate Measuring Machine (CMM) represents the pinnacle of our inspection capabilities. This advanced tool allows for the measurement of the geometry of physical objects with an unprecedented level of accuracy. By enabling precise dimensional analysis and geometric inspections, the CMM ensures that each product from M&M International not only meets but often exceeds industry standards.

The benefits of implementing such thorough quality control processes are profound and far-reaching:

Our dedication to rigorous quality control inspections underscores our commitment to excellence in manufacturing engineering. It is not merely about adhering to standards—it’s about setting them. At M&M International, we understand that our responsibility to our customers extends far beyond the production line. By investing in advanced quality control measures, we ensure that every product we deliver is capable of performing under the most demanding conditions, maintaining the high standards that our clients have come to expect from us.

We invite you to learn more about our commitment to quality and explore how it can enhance the safety, efficiency, and performance of your operations. Trust M&M International to provide not just products, but reliable solutions engineered for your success.

%20(3).png?width=123&height=123&name=_(250%20x%20250%20px)%20(3).png)

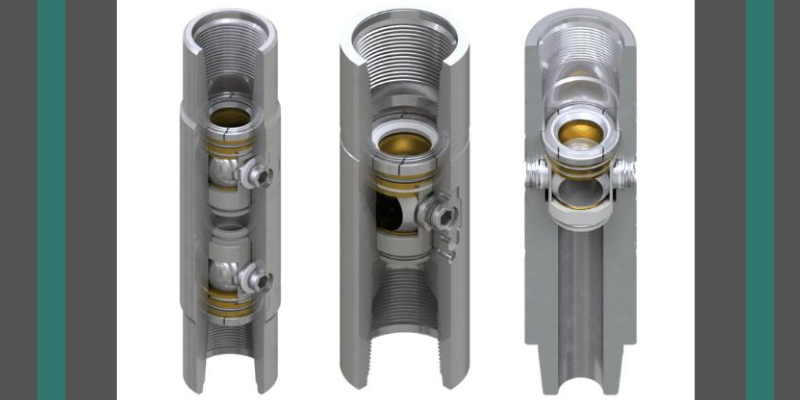

M&M International is a family owned and operated original equipment manufacturer in the energy industry. Since its founding in 1980, M&M has become internationally known in the industry for creating and manufacturing the most efficient, reliable, and user-friendly well control valve design in the world, namely, the CANISTER GUARD®.

M&M also manufactures a wide variety of subs, inside blowout preventors (“IBOPs”), swivels, surface test trees, offline cementing valves, and other equipment used during drilling, completion, and production operations, both on land and offshore. In addition to our products, we also offer a full spectrum of manufacturing services and stand ready to build not only our own designs, but the designs brought to us by our customers and partners.

The M&M International Team is committed to solving the most common, and uncommon, problems associated with the well control sector today. We also put forth great effort assisting our customers in solving problems associated with other aspects of the energy industry. We are a dynamic and customer satisfaction-oriented company that is focused on helping its customers improve on multiple levels, not just with their well control needs. No matter what we are doing for the customer, we deliver extraordinary service that is superior to any of our competitors.

Located at 1249 Evangeline Thruway, Broussard, Louisiana 70518

One film. One Story. One big win. We're proud to share that Outfox & M&M International have been honored with a Gold Telly Award for our cinematic

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

M&M International Welcomes NEOP, LLC as an Authorized Distribution Partner for the Appalachia Region and Michigan

In the high-stakes world of oil and gas drilling, operational safety is paramount. Drill Stem Safety Valves play a critical role in ensuring the...

With a rich heritage spanning decades, M&M International has been at the forefront of crafting upper and lower top drive valves. Engineered...

In the manufacturing and industrial sectors, the functionality and reliability of equipment are paramount. One of the key components that ensure...